Find your

passion in

the trades

Providing pre-apprenticeship, apprenticeship and certification training in the Piping Trades: Plumbing, Sprinklerfitting, Steamfitting and Welding.

UAPICBC is dedicated to providing an educational pathway for women, youth, newcomers, and Indigenous Peoples. Please contact our offices to inquire about our tuition free, funded programs and start your journey today!

Schedule

Check out the latest course scedule to find when classes are running.

Admissions

Find out more information about how to apply to UAPICBC, available financial aid and more.

FAQ

Have questions?

We have the answers here.

Programs

Your next oportunity starts here. Choose your program:

Pre-Apprenticeship

Pre-Apprenticeship programs provide you the fundamental skills necessary to succeed in your selected trade.

Apprenticeship

The apprenticeship programs gives you the opportunity to obtain your RED Seal certification, a nationally recognized certification.

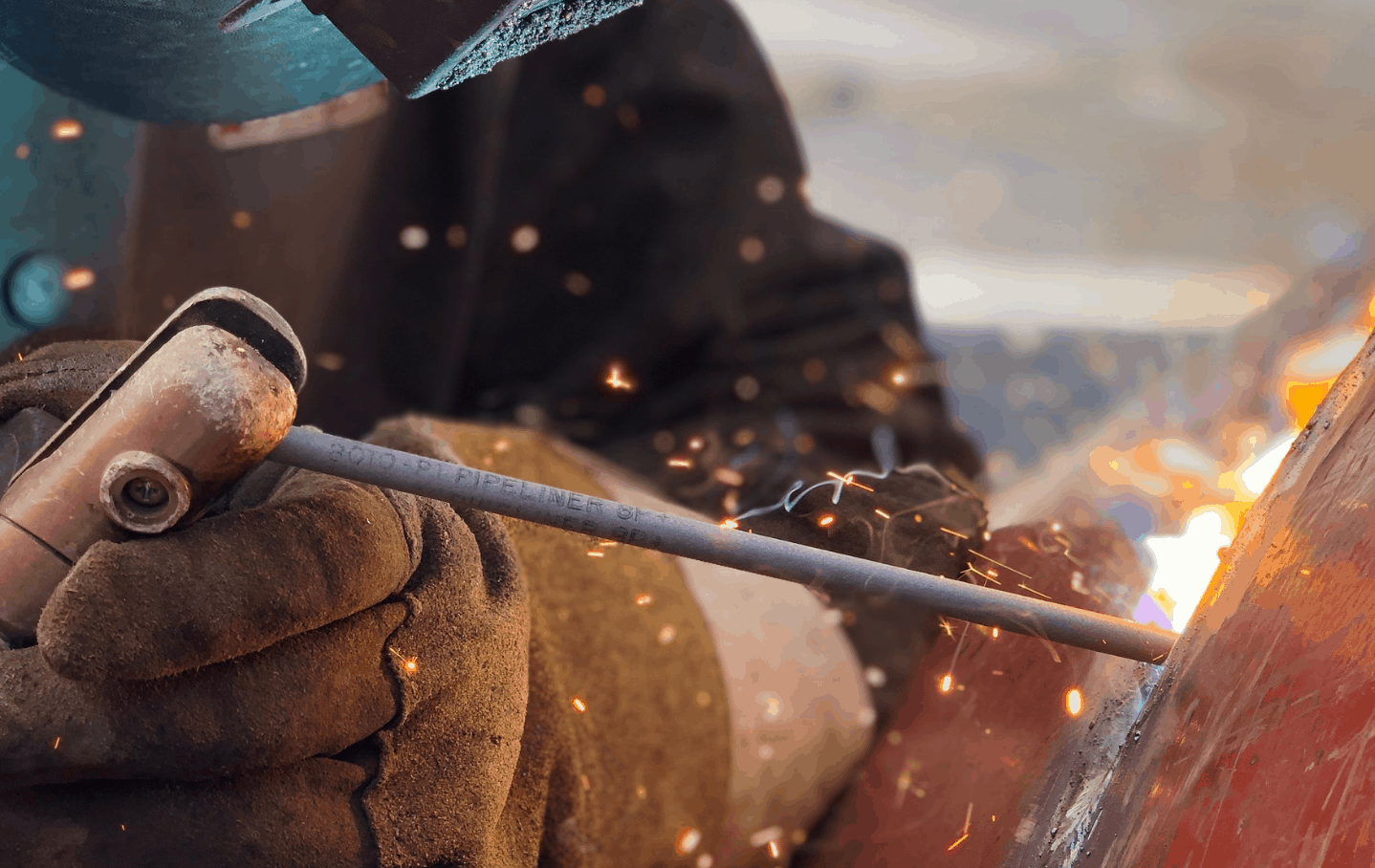

Welding

Ever been fascinated by the idea of joining metal? Interested in having a good-paying, portable, practical skill? Learning to weld can open many career doors.